The post-printing processes for labels, typically refer to a series of techniques such as die-cutting, lamination, glossing, hot stamping, embossing, etc., performed to enhance the aesthetic appeal and features of the product after printing. Among these processes, die-cutting is an essential technique for shaping labels and has seen continuous innovation in recent years, becoming a significant driving force for the profit and transformation upgrade in the label printing industry. Currently, label die-cutting processes in China are evolving towards digitization, intelligence, functionality, and interconnectivity.

Current Development of Label Die-Cutting:

In terms of die-cutting machine types, die-cutting machines, as one of the main devices for post-printing label processing, have undergone continuous updates. They have evolved from simple vertical manual die-cutting machines, semi-automatic flatbed die-cutting machines, to the present fully automatic flatbed die-cutting machines, rotary die-cutting machines, and various other forms, meeting the diverse demands of the domestic market for die-cutting equipment.

Regarding die-cutting techniques, common ones in the market include CNC engraving, flatbed die-cutting, rotary die-cutting, digital die-cutting, and more. CNC engraving relies on computer software for control, eliminating the need for plate making. It is suitable for sampling or short-run production but is relatively slow. Flatbed die-cutting uses a flat die-cut plate for continuous pressing, with advantages in lower plate-making costs compared to rotary die-cutting. However, it requires skilled operators and produces more vibration and slower production speeds than rotary die-cutting.

Rotary die-cutting, commonly using magnetic die-cutting, consists of magnetic rollers and die plates. It can be categorized into continuous and intermittent types. Intermittent rotary die-cutting allows for easy die changes, significantly reducing plate-making costs. The advantages of rotary die-cutting include high speed, efficiency, suitability for medium to long runs, straightforward setup, and lower labor costs. However, the cost of magnetic rollers is higher compared to flatbed die-cutting, and the machine’s price is generally higher.

With the development of digital printing technology, there is an increasing market demand for short to medium runs, personalization, and variable data. This has led to the emergence of digital die-cutting technology. The digital die-cutting process does not require plate making; the cutting head is controlled directly by a computer, enabling flexible and dynamic changes to die-cut patterns. Notably, modifications can be made even just before the die-cutting process, significantly reducing the production cycle.

Principles of Digital Die-Cutting:

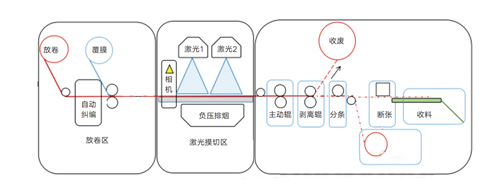

Digital die-cutting includes laser die-cutting and drag knife cutting, commonly referring to laser die-cutting. Laser die-cutting uses a high-energy-density laser beam to locally irradiate the surface of the raw material, forming vaporized grooves and completing the die-cutting process. As laser die-cutting does not require die plates during the die-cutting process, it is a non-contact die-cutting method. It avoids pressure during die-cutting, effectively preventing deformation at the cut edges and improving die-cutting compression resistance. Additionally, laser die-cutting can achieve full through-cutting, light scoring, semi-transparency, and other effects.

In conclusion, digital die-cutting, especially laser die-cutting, offers flexibility and versatility in die-cutting processes, catering to the growing demands of the market for customization, personalization, and variable data. The digital die-cutting industry is continually advancing, driven by technological innovation and the changing landscape of the label printing market.

Compatibility of Laser System Software

Compatibility of Laser System Software

Taking Wenzhou Diancheng Machinery Co., Ltd.’s laser die-cutting machine as an example, the laser system software of this machine is compatible with various computer systems such as WinXP 32-bit, 64-bit, Win7 32-bit, 64-bit, Win8 32-bit, 64-bit, etc. It is applicable to software compatible with Windows systems, including CorelDRAW, CAD, Photoshop, Word, Excel, and others.

Advantages of Digital Die-Cutting Technology

Compared to traditional die-cutting processes, digital die-cutting technology possesses significant competitive advantages in production efficiency and flexibility, gradually becoming the mainstream application in the market. From a process perspective, digital die-cutting offers numerous advantages.

Click to learn more about book printing, sticker printing, medicine box, hardcover book printing, PE bag, Bible printing, paper bag printing, catalog printing, and printing in China.

Personalization and High Precision In terms of flexibility, digital die-cutting technology allows the laser head to move in any direction during die-cutting, capable of cutting out any desired complex shape. Moreover, the shape of each die-cutting unit can be altered during operation, ensuring the realization of personalized label die-cutting.

Precision is a strength of digital systems, effortlessly achieving small die-cutting tolerances. It can even compensate for inherent accuracy errors in printing and post-processing (materials may stretch during printing and post-processing, and digital die-cutting can automatically adjust accuracy based on specific conditions).

No Need for Plate Making, High Efficiency Digital die-cutting eliminates the need for die plates and can cut the material into the required shapes without using additional tools or punching. It can respond immediately to customer requirements, saving time in plate making, with quick changeovers, short production cycles, and high production efficiency. Additionally, digital die-cutting can efficiently perform scoring operations, and the scored patterns can be modified at any time without interrupting production, significantly saving production time.

Furthermore, from an aesthetic perspective, digital die-cutting has many advantages. Since digital die-cutting involves no pressure, it does not damage the cut material. Especially for textured labels, digital die-cutting offers better peelability compared to traditional rotary die-cutting.

In recent years, with the rapid rise of digital printing to meet the market’s demand for short and small orders and the industry’s transition to a younger workforce, the simplified and convenient digital die-cutting post-printing process is gradually becoming the mainstream in the post-printing market. Therefore, the author is optimistic about the development of digital die-cutting technology in the label industry. In the future, digital die-cutting will enjoy even greater market prospects.

Comments

No comments yet. Be the first to react!